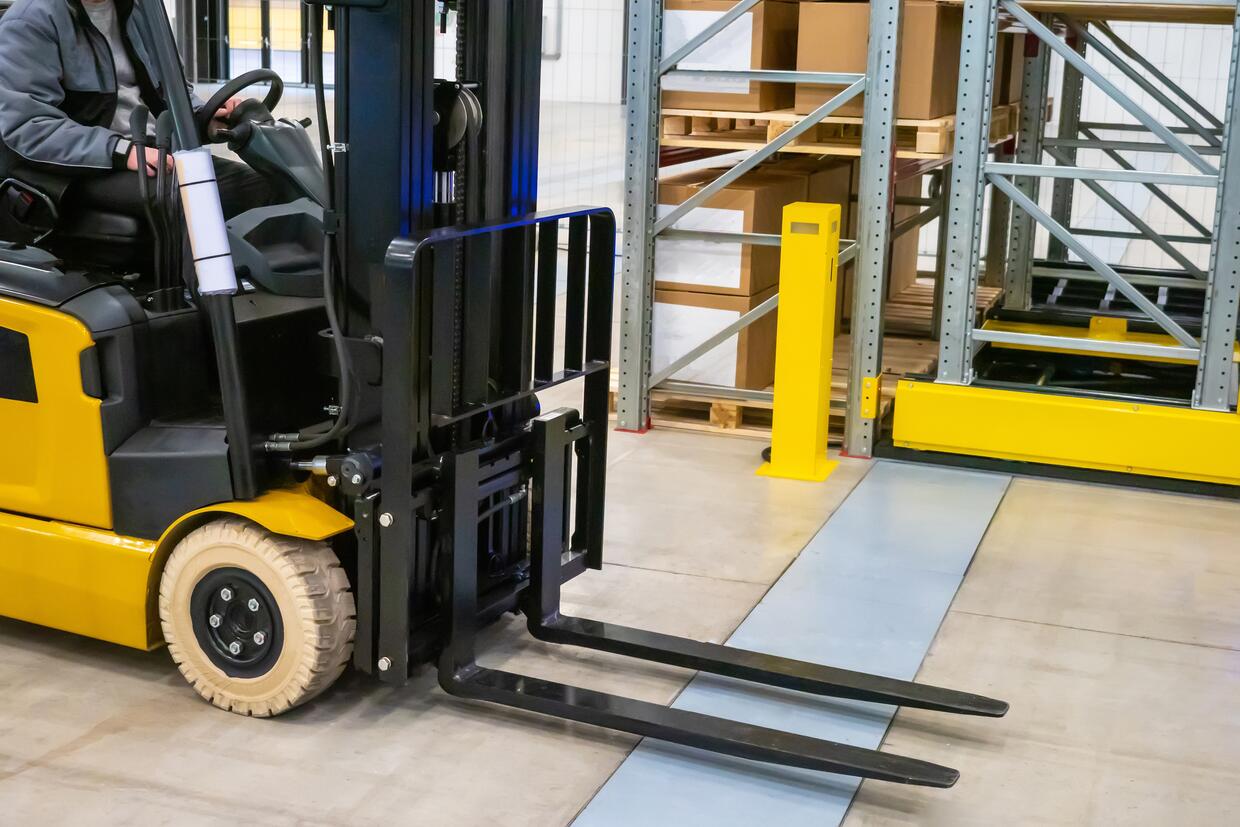

A forklift is one of the most recognizable industrial vehicles. Most people only know it as equipment for lifting and carrying heavy objects within a warehouse or docking site. Forklifts can do more – but to understand the breadth of their capabilities, you need to know their components and how they work.

Read on for a comprehensive list of forklift part names and functions.

What Is a Forklift?

A forklift is a motor-powered industrial truck to lift and move large, heavy objects – usually pallets and boxes – within a warehouse or compound. They are commonly used where palleted or boxed goods are constantly moved from one point to another (i.e., loading dock to storage to shipping dock).

Here are examples of facilities that often use forklifts:

- Warehouses

- Shipping docks

- Storage and distribution centers

- Logistics and transport facilities

- Construction sites

Forklifts come in different sizes and forms, but they all have a spacious seat with an overhead guard for the operator, who also acts as a driver and lift controller. An experienced operator can effortlessly lift a heavy pallet and drive without incident towards the designated unloading station despite their vision being partially blocked by cargo.

Anyone working on sites using these machines should know the different forklift part names and their functions. Familiarity with heavy equipment and industrial machines helps people be more careful and mindful of the safety best practices. With this in mind, let’s proceed with knowing the components of a forklift.

Parts of a Forklift

A forklift looks smaller and more bare than other industrial machines and vehicles. Still, it has many moving parts that must work harmoniously together for operators to safely and efficiently perform their tasks.

There are three major parts of a forklift:

- Chassis

- Mast

- Overhead Guard

Chassis

A closer look at the components of a forklift contained inside the chassis reveals four parts:

- The Counterweight – You will notice that a forklift has a hefty body with a rear end that looks like a hulking assembly of metal. This is because the body needs to counterbalance the maximum weight the forks can lift. The last thing you want to happen is for the machine to tip over forward when picking up cargo because it is too heavy on the front.

The counterbalance ensures proper weight distribution throughout the forklift, whether with or without a load. Of course, there are limits to how much a forklift can lift and carry over a distance. The rule of thumb is that the load should not be heavier than the counterweight.

- Engine and Battery – The engine and battery compartment are concealed under the operator’s seat and sit directly on top of the counterweight. They add weight to the chassis, further balancing the weight distribution when the vehicle carries and moves a load.

Fuel-powered forklift engine compartments include the transmission, fuel system, radiator and cooling system, hydraulic valve, pump, tank, air intake, and electrical fuse box. An electric forklift setup is more straightforward because the compartment only contains the battery, hydraulic systems, and electrical controllers.

- Operator Compartment – The operator compartment is dedicated to the technician and driver. It is spacious, open, and has a single seat.

A steering wheel is directly in front with four pedals below it: (from left to right) a parking brake, an inching pedal, a service brake, and an accelerator.

Right next to the steering wheel are at least three levers that control the forklift’s hydraulics: (from left to right) to lift and lower, tilt, and control carriage attachments. A warning or safety horn is within arm’s reach from the seat, allowing the controller to signal anyone approaching the forklift when it is moving while carrying cargo.

A gauge screen or digital display showing vital information about the vehicle, like a speedometer, engine temperature gauge, and other warning indicators is usually mounted on the chassis.

Lastly, a forklift must display a data plate in the operator compartment. The data plate contains information about the machine, like the model, type, tire sizes, weight, and lifting capacities.

Among the parts of a forklift, the operator compartment resembles a car the most. The lever controls are similar to a gear shift stick, and the pedals are similar to a manual transmission car. This explains the preference for people with driver’s licenses to become certified forklift operators.

- Wheels and Tires – Forklifts have two sets of wheels: the drive wheels (front) and steer wheels (rear).

The drive wheels serve as a fulcrum or balancing point that bears the weight of the load as the forks lift. Hence they are larger and have bigger tires than the rear wheels. The engine supplies power to these wheels, which are responsible for moving the truck forward. The drive wheels have a fixed, front-facing position to provide stability and support.

The steering is done from the rear. The steering wheels can turn left and right and change the direction of the truck’s body as it moves forward. They are small, but they can support the collective weight of the operator, chassis, and contents of the engine compartment.

Depending on the forklift’s size and maximum weight capacity, it can have average-sized tires filled with air, just like regular cars, or massive solid pneumatic tires filled with foam. Another variation is cushion tires., which are solid rubber molded on a circular steel band.

Air and cushion tires are ideal for indoor use because they are prone to punctures from nails, sharp rocks, and debris. Solid pneumatic tires, being bigger with large treads, are better suited for outdoor or construction environments.

Mast

The forks of a forklift are attached to the mast. The mast is the entire front side of the truck consisting of a frame that holds the mechanism and hydraulics responsible for lifting and lowering the fork. Also called the “upright,” the mast is made up of rails, cylinders, chains, and a carriage.

- Rails – These form the frame that indicates the maximum fork height. Depending on the type of forklift, the rail can extend higher than the chassis and increase the maximum lift height to deposit loads at elevated spots, like in a stacked container van or second-story shelving.

- Lift Cylinders – These hydraulic cylinders are strong enough to lift the mast and loaded fork. Depending on the model and carrying capacity, a forklift can have free lift cylinders (mounted at the center of the mast), outboard cylinders (mounted at the rear of the mast and used in nested extendable rails), or tilt cylinders (mounted at the back of the mast, allowing it to push or pull a load atop the fork.

- Chains – The chains are attached to the carriage and work with the cylinders to lift or lower the fork.

- Carriage – The carriage is the square-like, vertical grid frame in front of the mast. The carriage is attached to the chains and has mounting rails where operators can mount or bolt forklift attachments. There are five classes of carriages, with Class 1 being the smallest with the lightest weight capacity (less than 2,200 lbs) and Class 5 being the biggest with a lifting capacity of almost 25,000 lbs.

What about the fork?

Forks are attachments mounted on the carriage and measure 42 to 96 inches long. Operators can swap them out according to size and weight-lifting requirements.

Other attachments or components of a forklift that can be mounted to the carriage or mast itself are:

- Sideshifters – These are horizontal bars with indents that are mounted on a carriage. The forks are then hooked on the side shifters. If the load is wide, forklift operators can adjust the position of the forks and move them further apart on the side shifters for better weight distribution.

- Fork positioners – A step up from regular side shifters, fork positioners have hydraulics that allows operators to adjust the positions of the forks quickly. These are useful when transferring different-sized pallets for which operators need to realign the divisions to match each pallet’s size.

- Paper roll clamps – As the name suggests, these attachments look like giant, curved clamps designed to hold and lift cylindrical paper rolls instead of balancing them precariously on top of the fork.

- Single-double pallet handlers – Like the paper roll clamps, these specially-designed attachments enable operators to lift two or more pallets simultaneously. These multiple-pallet handlers are two pairs of forks that raise and lower as one.

- Slip sheeters – This attachment has a hydraulic, retractable arm that “grabs” onto a slip sheet beneath a load, then pulls the entire cargo onto the fork.

Overhead Guard

The overhead guard is pretty straightforward: its purpose is to protect the operator from falling objects. It also provides necessary cover from the heat when driving the forklift truck outdoors.

Since the overhead guard creates a frame of sorts over and around the operator, it holds extra features to ensure the safety of the operators and anyone nearby while the truck is in operation. These safety features include:

- Headlights – Mounted on the upper portion of the front left and right pillars, the headlights offer better visibility, especially in dark, smoggy outdoor environments

- Mirrors – Mounted on the same spot as the headlights but facing the operator, the left and right mirrors show the forklift’s rear so the operator doesn’t have to turn to check for people, vehicles, or objects behind him.

- Warning lights – Usually mounted directly above the operator, it flashes a blue light to warn pedestrians and other vehicles of the forklift’s approach. The warning lights also flash red when people stand too close to the forklift.

- Brake and turn signal lights – Mounted on the topmost frame of the overhead guard, these lights function precisely like the brake lights and turn signals in cars.

Importance of Forklifts in Material Handling

Now that we’ve covered the different forklift part names, descriptions, and functions, let’s briefly discuss why they are necessary for logistics and warehousing.

- Forklifts are easy to maneuver in a crowded warehouse. It can fit past narrow aisles, which means warehouses can utilize more floor space for vertical storage.

- They are smaller than most industrial vehicles but are more effective at moving cargo from one place to another.

- They use different fuel types, like LPG, diesel, and propane. Some manufacturers have also produced purely electric forklifts. Facilities can pick a model whose fuel is abundant or cheaper in their region.

- There are models for indoor and outdoor use.

- Certain parts, like the tires, can be customized to meet a facility’s hygiene and safety protocols.

- Facilities only have to buy attachments to expand their forklift capabilities instead of acquiring new, more expensive lifting machines. The paper roll clamps are an excellent example.

Interested in acquiring a forklift but need more capital to purchase a brand-new truck? Consider renting from a reputable professional procurement company specializing in construction and industrial equipment leasing.

National Dispatching is a one-source site for industrial vehicle and equipment rentals. We serve contractors in the construction, communications, and logistics sectors. We are committed to helping clients operate more safely and efficiently. Our ultimate goal is to improve client profitability and help them create thriving and efficient workplace environments.

Check out our forklifts and material handling equipment, and contact us to discuss your rental, materials, trucking, or subcontracting needs.